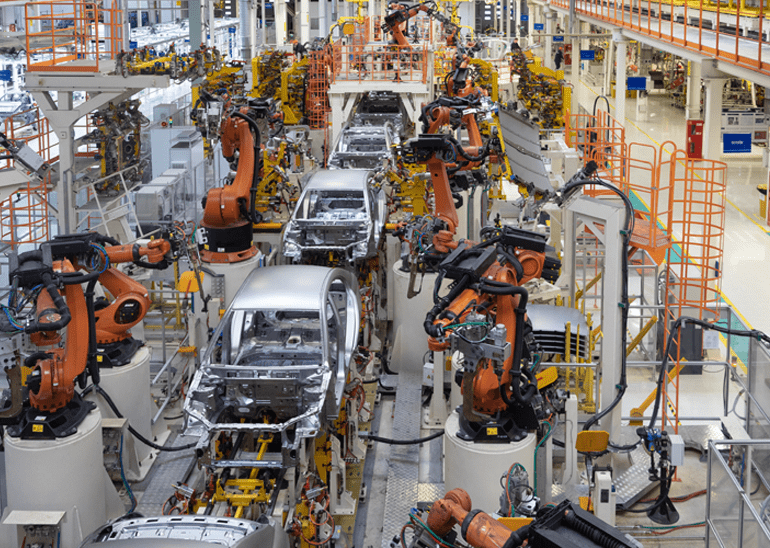

Improving quality;

Comprehensive quality management capabilities, extending from the arrival terminal to the production and business offices.

Throughput of speed

Activating agile production processes, streamlining processes, ensuring end-to-end control and visibility to meet changing customer and market needs.

Cost reduction

Intelligent management of materials, machines, and manpower to reduce costs, increase capacity, and reduce delays.

Aiiiss-MOMSolutions are helping auto parts manufacturers improve quality and traceability, increase production control, reduce rework, and reduce costs.

Reduced rework and commissioning time;

Accelerated Product Release

RaiseOEEAnd productivity

Some of the clients we've helped